System Supply & Safety Component (S3C)#

General#

Device: Lattice Mach XO2

Part: LCMXO2-4000HC-4TG144C

Designator: U19

Supplied by 3V3_S3C, 3V3_PER, 1V8_PER and (if needed) 1V8_S3C

Integrated Flash memory for configuration storage (bitstream)

Programmable via JTAG, SPI (PS-SPI0) and I²C (PS-I2C1)

No external clock source integrated on carrier

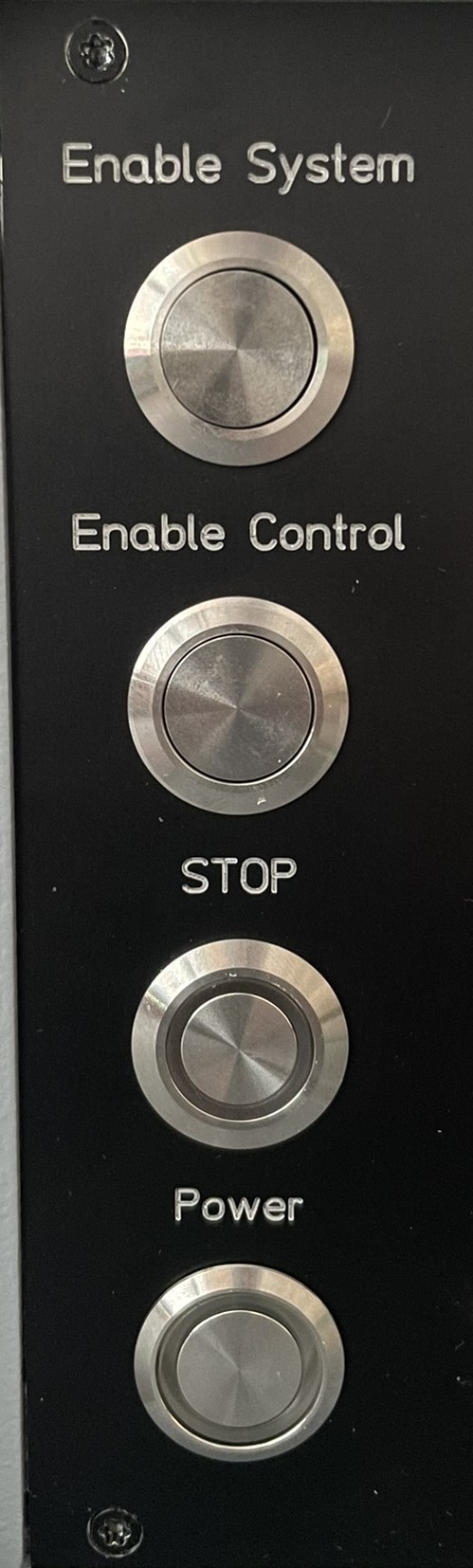

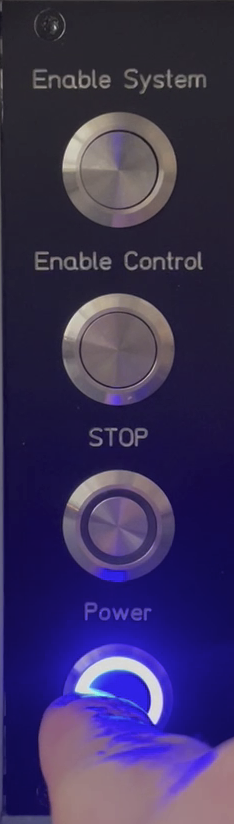

Unlike in previous revisions of the UltraZohm,

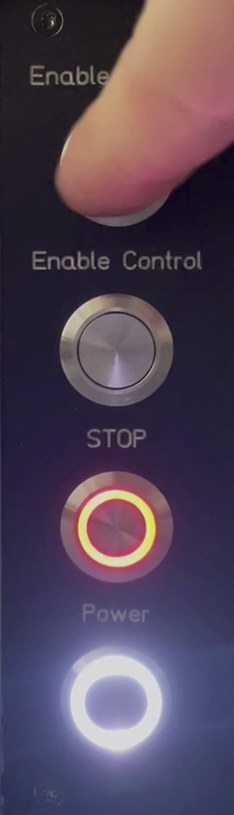

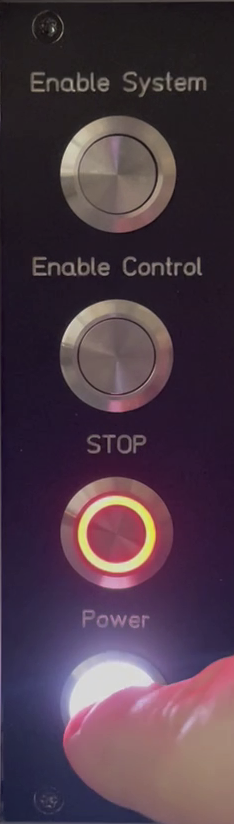

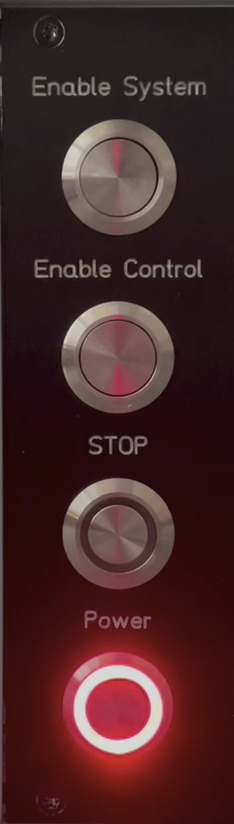

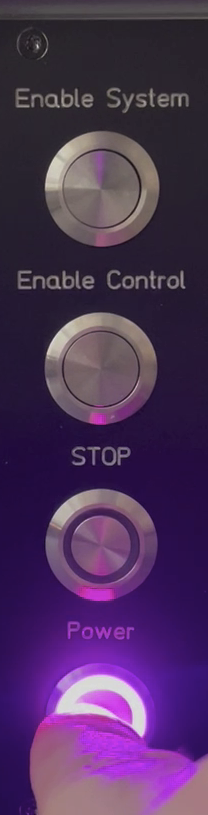

the frontpanel no longer comes with a red power switch (previously located between the 24V power supply and the carrier), and

the various on-board supplies (derived from the incoming 24V) no longer power up automatically after the 24V are switched on.

Instead, there now are

a “first-level” power switch on the backpanel (as part of the line-supply connector assembly), and

a “second-level” power button on the frontpanel (that replaces the aforementioned red switch).

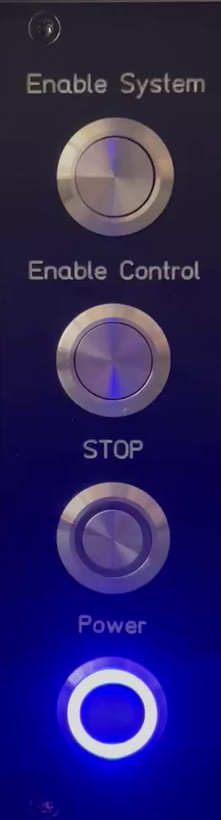

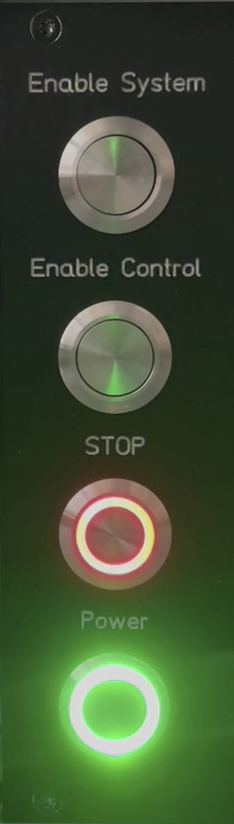

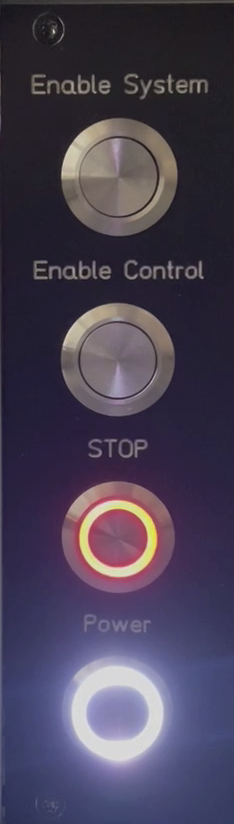

When the backpanel-side switch is on, the PSU’s 24V only power up a newly-added supply rail dedicated to the S3C (3V3_S3C). All other rails are ramped up as soon as the user presses the frontpanel-side power button, which is monitored by the S3C. Then, the well-known ramp-up sequence of previous carrier boards is started by enabling the now-default-off 3V3_MOD (U10).

Statemachine for S3C#

stateDiagram-v2

state UZ {

[*] --> Waiting_for_Powerbutton_pressed

Waiting_for_Powerbutton_pressed --> Waiting_for_Powerbutton_released

Waiting_for_Powerbutton_released --> Wait_State

Wait_State --> EthernetPhy_Reset

EthernetPhy_Reset--> Ready_State

Waiting_for_Powerbutton_pressed_2sec --> Ready_State

Waiting_for_Powerbutton_pressed_2sec --> SoftError

Waiting_for_Powerbutton_pressed_2sec --> Warning

Operation --> Waiting_for_Powerbutton_pressed_2sec

state Operation {

Ready_State --> Warning

Ready_State --> SoftError

Warning --> SoftError

SoftError --> Warning

SoftError --> Ready_State

Warning --> Ready_State

}

Waiting_for_Powerbutton_pressed_2sec --> Waitingfordslotdown

Waitingfordslotdown --> Waiting_for_Powerbutton_released2

Waiting_for_Powerbutton_released2 --> Waiting_for_Powerbutton_pressed

}

UZ --> HardError

HardError --> Acknowledge_Error

Acknowledge_Error --> Waiting_for_Powerbutton_released2

Functions#

Default routes of “pass-through signals”

FrontpanelIO.ExternalSTOP-debounce->FlexMIOs.61_ExternalSTOP(add latch functionality? reset by power cycle?)FlexMIOs.52_PCIe-R̅S̅T̅->FrontpanelIO.FlexMIO52_PCIe-R̅S̅T̅(depending on PS configuration, an inversion might be required)[do not implement until supported by the configuration of the PS!]

SD0_CD(and, later,SD1_CD, if implemented) ->FlexMIOs.45_SD-CD(depending on PS configuration, an inversion might be required)[do not implement until supported by the configuration of the PS!]

FrontpanelIO.isoCtrl.I̅N̅T̅->FlexMIOs.54_I2C0-SharedI̅R̅Q̅

Other defaults

SD_SEL: For the time being, this signal shall be driven to'0'FrontpanelIO.isoCtrl.R̅S̅T̅: For the time being, this signal shall be driven to'1'

Power sequencing

On power-on of the S3C, drive

Carrier_PwrOnlow and keep it there, then check whetherSysSW_Pwr_NCis high (delay required, probably)On a (debounced, cf. above) falling edge on

SysSW_Pwr_NC, initiate the power sequencing (hem) sequence byasserting

Carrier_PwrOn,waiting for

PG_Moduleto (de?)assert, and then, after some ms-range delay,switching

Carrier_PG_1V8(cf. below) from'Z'to'0'for some time and releasing it again (to'Z').Of course, various LEDs are available to signal this process to the user ;-)

For the time being, power-off shall be initiated by a second-long low signal level on

SysSW_Pwr_NC, i.e., holding the power button. For any future versions of this bitstream (on the S3C) anduz_sw(on RPU and APU), a notification to software shall be added (in particular when logging to the SSD is used).Current usage of power good (aka not-reset) signals

Carrier_PG_1V8: Connected toRESETnof the two Ethernet PHYs (carrier and frontpanel-main, 10k pullup on carrier)Carrier_PG_3V3: Enables the DC/DC converter of the isoIO island’s 3V3 rail (on frontpanel-main, no pullup/down R)

Default safety interaction between the System Controller (S3C) and the five D-Slot Controllers

The carrier board’s standard safety concept relies on a fixed set of hand-shake lines that flow between the Digital Slots, the System Controller (S3C), and the D-Slot CPLDs.

The schematic of this interface can be found in the carrier-board design documentation (see page 60 of the PDF)

See Overview of the signal groups between S3C and D-CPLDs below for an extended explanation of the signals

Color |

Conceptual name |

Direction |

Rail |

Explanation |

|---|---|---|---|---|

Black |

5x PILOT_OUT / Output-Enable |

S3C → Slot connector |

3V3 |

Final “enable the card`s outputs” to the slot signal. One line per slot |

Blue |

FLT (Safe-state request) |

S3C → Slot Controller |

1V8 |

Asserted whenever any fault or the external stop asks the whole system to go safe. All slot controllers must react to it |

Purple |

CarrierRdy (x1) |

S3C → Slot Controller |

1V8 |

Tells the slot controller that the main carrier (SoC + power rails etc.) is up and running |

Red |

5x !FLT / per-slot fault |

Slot Controller → S3C |

1V8 |

Each slot pulls its own line low to request a safe state (over-current/temperature/firmware error …) |

Green |

5x OE |

Slot Controller → S3C |

1V8 |

The slot’s internal AND of PILOT_IN (card`s “I’m ready” signal) and its own health. High = “it is safe to enable my outputs” |

Grey |

PILOT_IN (becomes FLT after fusion in slot c.) |

Slot connector → Slot Controller |

3V3 |

just reminds you that the raw card contact is OK; used locally inside each slot controller when it builds its OE and fault logic |

The table above lists every signal, its direction, and its purpose.

These links form the default interaction path implemented in both the S3C bitstream and the D-Slot Controller.

The Request-OE signals (green) – which themselves might depend on the card-local PILOT_IN – effectively are “looped through” the S3C and reach the actual D-Slot slots/cards as Output-Enable (black).

Default logic in the S3C bitstream

The S3C side contains a conditional pass-through that propagates the SlotOE request only when no system-wide force-disable is active:

-- Conditional passthrough for OE

DIGS3C_SlotD_SlotOE <= DIGS3C_SlotD_ReqOE and (DIGS3C_SlotD_SlotOE'Range => NOT forceoutputdisable);

At present, only SlotOE is actively driven. Other potential outputs – such as the S3C’s CarrierRdy – are left unconnected and therefore idle.

Default logic in the D-Slot bitstream

The D-Slot CPLD feeds two status signals back to the S3C:

ReqOE: mirrors the S3C’s output-enable request so the controller can perform integrity checks.

SlotOK: asserted when the S3C has not requested a safe state; it drops low whenever a fault is forced.

Detailed VHDL assignments for the D-Slot Controller are included in Create a CPLD program using Lattice Diamond.

Extending the default behaviour

The current assignments merely establish the mandatory signal directions and the minimal “safe-default” logic. If your application needs tighter supervision or additional routing, you can:

hook extra internal state machines into these nets

expose further pins on the D-Slot connector, or

redefine the pass-through conditions entirely.

In short, while the template guarantees a fail-safe baseline, it is designed to be adapted to any project-specific safety or forwarding requirement.

I/Os#

Static system-level I/O assignment

Inputs

Power sequencing and monitoring:

PWRMON.PG_VIN,PWRMON.P̅P̅_VIN,THERMAL_DATA.S̅H̅D̅N̅,THERMAL_DATA.F̅F̅/F̅S̅,THERMAL_DATA.A̅L̅E̅R̅T̅,PG_ModuleFrontpanel:

FP_UsrSW[1-3],SysSW_Pwr_NC(power button),FrontpanelIO.ExternalSTOPOther system functions:

SD[01]_CD,FlexMIOs.52_PCIe-R̅S̅T̅isoIOs:

FrontpanelIO.isoCtrl.I̅N̅T̅Slots:

ANL_S3C.SlotOK[1-3],DIG_S3C.SlotD[1-5].ReqOE,DIG_S3C.SlotD[1-5].SlotOK

Outputs

Power sequencing and monitoring:

Carrier_PG_1V8and_3V3,Carrier_PwrOnFrontpanel:

FP_SysLED[rgb](RGB LED of power button),FP_SysLEDs(red LED of stop button),FP_UsrLED[1-4]Other system functions:

SD_SEL,FlexMIOs.45_SD-CD,FrontpanelIO.FlexMIO52_PCIe-R̅S̅T̅,FlexMIOs.54_I2C0-SharedI̅R̅Q̅,FlexMIOs.61_ExternalSTOPisoIOs:

FrontpanelIO.isoCtrl.R̅S̅T̅Slots:

ANL_S3C.CarrierReady,ANL_S3C.P54_Legacy,DIG_S3C.Shared.CarrierReady,DIG_S3C.SlotD[1-5].SlotOE,DIG_S3C.Shared.ReqSafeState

Special functions

JTAGENB(see this post in issue 127 for required config. option)Pins 126/125 (primary I²C)

Pins 105/106 (secondary I²C)

Dynamic application-level I/O assignment

FrontpanelIO.isoSigs.FlexIO0[1-5]can be used to drive the last five isoIOs (i.e., fromIO09onwards) as 2x output, 2x input and 1x output (in that order) – So the signal directions are fixed, but function is freely programmableThe six

FlexLIOs[0-5](flexible logic/PL IOs) are available between the S3C (and thus everything reachable from it) and the Zynq’s PLThe S3C’s twelve

DIG5_S3Csignals (00-05, 24-29) complement the SoM’s 18 signals that interface slot D5

Input-specific processing requirements

Do not rely on unless UZ is switched on (i.e.,

Carrier_PwrOnis asserted) AND fully supplied (i.e., no power alert signals are asserted):FP_UsrSW[1-3],FrontpanelIO.ExternalSTOP,FrontpanelIO.isoSigs.FlexIO0[1-5],FrontpanelIO.isoCtrl.I̅N̅T̅,THERMAL_DATA.S̅H̅D̅N̅,THERMAL_DATA.F̅F̅/F̅S̅,THERMAL_DATA.A̅L̅E̅R̅T̅, and - to a certain extent -PG_MODULEIn transitionary states (e.g., the system is losing its supply), additional care is required for all signals as their respective supply rails might ramp down in an instance-variant manner

Debounce filtering:

SysSW_Pwr_NC,FP_UsrSW[1-3],FrontpanelIO.ExternalSTOP– Note that all the above signals are low-active, i.e., high as long as the corresponding button is not pressed

Output-specific processing requirements

Set to

'Z'unless UZ is switched on (i.e.,Carrier_PwrOnis asserted):FrontpanelIO.isoSigs.FlexIO0[1-5],FrontpanelIO.isoCtrl.R̅S̅T̅,FrontpanelIO.FlexMIO52_PCIe-R̅S̅T̅– Note that the above list will get considerably longer if R44 is populated (instead of R43). In that case, care has to be taken w.r.t. S3C bank 2 (i.e., U19C) driving current into powered-off components!